|

|

|

07831 111471 |

|

sales@retro-uk.com | |

|

For all the difficult to find period accessories which will give your car that finishing touch. |

|||||

| HOME | PARTS INDEX | PICTURE GALLERY | PARTS ARCHIVE | ||

|

|

|

07831 111471 |

|

sales@retro-uk.com | |

|

For all the difficult to find period accessories which will give your car that finishing touch. |

|||||

| HOME | PARTS INDEX | PICTURE GALLERY | PARTS ARCHIVE | ||

PROTECTION AGAINST ETHANOL AND ITS CORROSIVE PROPERTIES WHICH IS A THREAT TO ALL CLASSIC CARS

Fuels in the UK now contain ethanol, which has a corrosive effect on many metals and rubber. Classic car fuel systems are suffering with rubber pipes simply falling to pieces and steel tanks rusting inside. We hope the following products will be of help to classic car owners looking for a solution to this worrying problem.

UK DELIVERY ONLY

|

TAPOX Tank Sealant - Designed to Withstand 100% Ethanol Fuel (WW73200)

TAPOX Tank Sealant Designed to withstand 100%

Ethanol Fuel. Please note that this is an epoxy based product and recommended curing time is 120 hours. UK DELIVERY ONLY (Manufactured in Germany) |

£35.00 UK DELIVERY ONLY

|

|

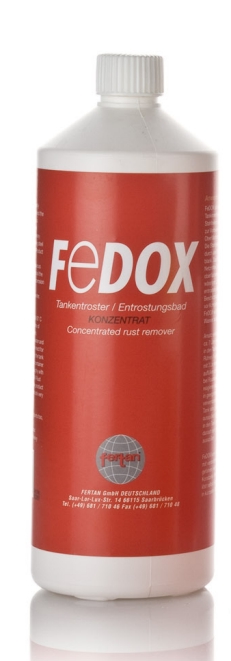

FeDOX Rust Removal Treatment Fedox is a compound specifically developed for cleaning of steel and the inside of fuel tanks and acts as a preparation for Fertan surface protection. With Fedox even heavy corrosion will be removed leaving steel and tanks bright and rust free. Product contains wetting agent and biodegradable surfactant in aqueous solution. UK DELIVERY ONLY

|

£20.00 UK DELIVERY ONLY |

|

Metal

tank treatments. In

all situations the surfaces to be treated should be cleaned with

detergent and degreased using a normal alkaline engine cleaner. We’ve

designed and manufactured three products to treat corroded steel and

iron. These are all

mentioned many times below so it is perhaps worthwhile discussing them

briefly to avoid tedious repetition later. Fertan

rust converter (FRC)

is our original and main product. Applied

to a rusted surface it will make its way through the rust to the

underlying steel and lay down a zinc layer.

The rust above it will be converted to iron tannate.

The majority of this will be bonded to the underlying substrate

but some will be left as a loose black dust on the surface which will be

rinsed off when the surface is wiped down to remove unused excess FRC.

The surface will be blue/black and resistant to corrosion.

It provides a perfect base for overpainting or the application of

cavity wax / underseals. FRC

is also 1

: 8 to |

|

A full printable version of Metal Tank Treatments and the TAPOX instruction leaflet are avaliable by clicking the following links: |